Description

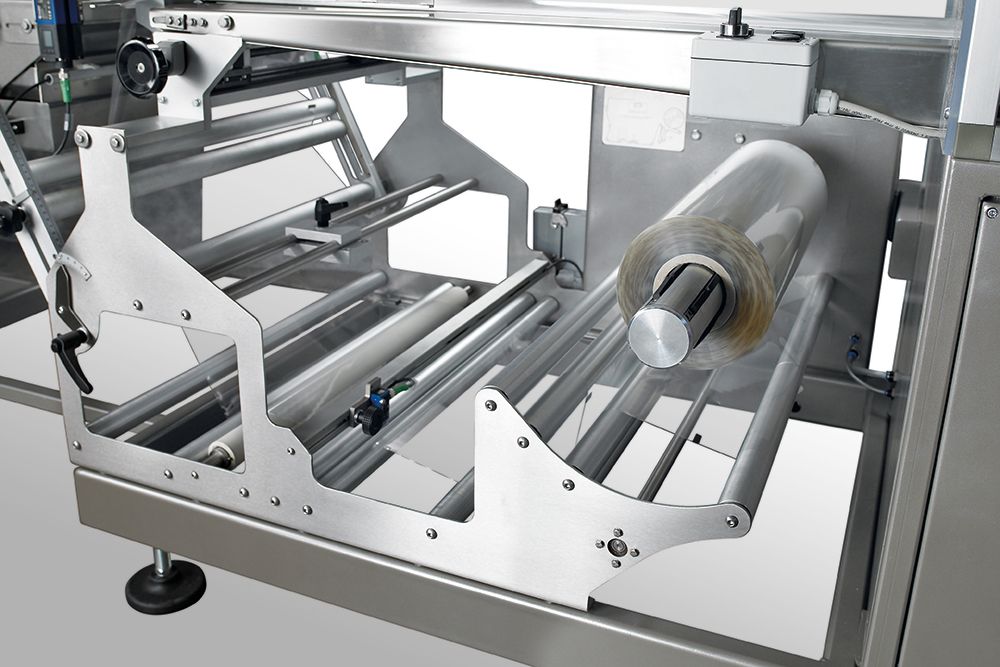

The GSP 65 EVO BB is an industrial machine dedicated to packaging long-life products by flushing gas or spraying on preserving aromas. It is specifically indicated for large, high or in-chain products, also using polyethylene/polyolefin film.

Years of design experience on modified atmosphere packaging machines led to the creation of a very fast, versatile machine for perfectly airtight packaging.

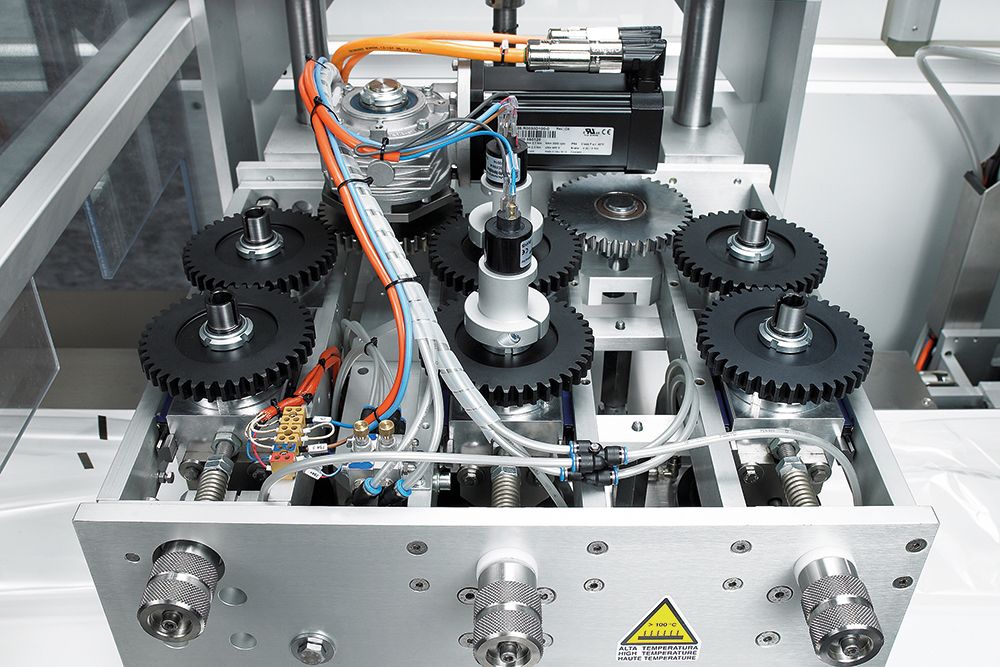

The transversal, box motion, electronically controlled sealing unit guarantees fast changeover and, on demand, gusseted and square shaped packages. The long-time sealing system combined with a low inertia leverage guarantees airtight sealing, putting high pressure on film. This system is ideally applie in the technical product sector, to welding film like polyolefin and polyethylene. On demand, package can have bead seals.

The GSP 65 EVO is also available in BB VERSION (reel coming from the bottom). Both versions can be equipped with a belted infeed and with the variable bag length feature.

Production speed:

Up to 60/70 ppm

Product dimensions:

Width: 10÷280 mm

Height: 1÷200 mm

Length: 50÷2000 mm

Reel dimensions:

Reel width 520 mm

Outside diameter: 350 mm

Core diameter: 70÷76 mm

Packaging materials:

Heat-sealable

Cold-sealable

Polyethylene

Polyolefn - Cast

Machine dimensions GSP65EVO-BB:

Length: 5400 mm

Width: 1350 mm

Height: 1600 mm

Compressed air:

7 bar dry and fltered air

- Motion control with PLC

- Interface through 5,7” touch screen

- Working programs memorization

- Machine diagnostic

- Temperature control through touch screen

- Power 5 kw

- Web width up to 720-920 mm

- Automatic flm splicer

- Gear shift for short/long pitch

- Double reel holder

- Gas fushing device for MAP

- Printing unit

- Photocell for print registred flm

- Euro-slot die cut

- No product no bag

- Automatically variable bag length

- No gap-no seal

- Film trimming unit

- Bead seal

- Gussetting device

- Automatic feeding system

- Polythene version

- Infeed extension

Many other solutions can be proposed by our technical team according to the various requirements.